Marcus Thompson stared at his August electric bill in disbelief: $387 for his 1,200-square-foot Phoenix apartment. His three-year-old "budget" mini-split ran constantly during Arizona summers, cycling on and off every twelve minutes like clockwork—full blast for seven minutes of deafening noise, then complete silence for five minutes while the temperature crept back up. The constant cycling destroyed sleep quality, and his infant daughter would wake crying every time the unit roared back to life. When his neighbor mentioned his similar-sized apartment cost just $160 monthly to cool with a newer system, Marcus assumed his neighbor must be exaggerating or had better insulation.

Then Marcus's contractor explained the culprit: his budget system used outdated fixed-speed technology without an inverter, while his neighbor's system featured DC inverter technology. "Your compressor is like driving with only the gas pedal floored or completely off—there's no in-between," the contractor explained. "Modern inverter systems run like cruise control, adjusting speed continuously to match exactly what you need." The difference wasn't subtle marketing spin—it was fundamental engineering separating 1980s technology from modern efficiency.

Marcus upgraded to a Zone 18K BTU inverter system. His first full month of operation during Phoenix's 105-110°F peak summer showed $168 in electricity costs—a $219 monthly savings. The unit ran nearly 24/7 at variable speeds between 30-80% capacity, maintaining rock-solid 73°F without temperature swings. The indoor noise dropped from conversation-level disruption to barely-audible whisper. His daughter slept through entire nights for the first time in months. Over the system's expected 18-year lifespan versus his old unit's remaining 7-9 years, Marcus will save approximately $47,000 in combined electricity costs and avoided early replacement.

This comprehensive guide explains exactly how inverter technology works, why it delivers 30-60% energy savings over traditional systems, and whether the modest purchase premium justifies the dramatic long-term benefits. If you've ever wondered why some mini-splits cost $1,200 while others cost $2,500 for seemingly identical BTU ratings, inverter technology is the answer—and understanding this difference could save you thousands over your system's life.

What is Inverter Technology?

Simple Explanation:

Traditional air conditioners work like a light switch - completely ON or completely OFF. Inverter technology works like a dimmer switch - adjusting power continuously from 20% to 100% capacity.

Technical Explanation:

An inverter converts DC (direct current) to AC (alternating current) at variable frequencies, allowing precise control of compressor motor speed. This enables the system to match output exactly to current demand.

Real-World Analogy:

Imagine driving from New York to Boston:

Non-Inverter Approach:

- Floor the gas pedal to 100 mph

- Coast when you reach destination

- Slam brakes, stop completely

- Repeat entire cycle when needed

- Result: Terrible fuel economy

Inverter Approach:

- Accelerate to cruising speed

- Maintain steady 65 mph

- Adjust speed slightly for hills

- Gentle deceleration at destination

- Result: Excellent fuel economy

Your mini-split's inverter does the same thing for temperature control.

How Inverter Technology Works

Starting the System:

Non-Inverter (Traditional):

- Compressor starts at 100% power

- Huge electrical surge (5-8x normal amperage)

- Full-blast cooling/heating

- Reaches temperature

- Shuts off completely

- Room temp drifts

- Starts again at 100%

- Repeat cycle

Inverter System:

- Compressor ramps up gradually

- Minimal electrical surge (1.5-2x normal)

- Reaches temperature efficiently

- Reduces to 20-40% power

- Maintains exact temperature

- Adjusts continuously

- Never fully stops (most of the time)

The Magic: Continuous Microadjustments

Every few seconds, the inverter:

- Reads room temperature

- Compares to setpoint

- Calculates needed capacity

- Adjusts compressor speed

- Optimizes efficiency

- Maintains comfort

Energy Efficiency Benefits

Starting Energy Savings:

Traditional System Start:

- Inrush current: 40-60 amps

- Duration: 1-3 seconds

- Energy waste: Significant

- Stress on components: High

Inverter System Start:

- Inrush current: 12-18 amps

- Duration: Less than 1 second

- Energy waste: Minimal

- Stress on components: Low

Operating Efficiency:

Non-Inverter:

- Runs at 100% or 0%

- Average efficiency: 60-70%

- Constant on/off cycling

- Poor part-load performance

Inverter:

- Runs at 20-100% as needed

- Average efficiency: 90-95%

- Minimal cycling

- Excellent part-load performance

Real-World Impact:

Let's compare cooling a 350 sq ft room on a moderately warm day (needs about 40% of unit capacity):

12,000 BTU Non-Inverter:

- Runs full blast 4 min → Off 6 min

- Cycles 6 times/hour

- Power consumption: 1,100 watts average

- Monthly cost (10 hr/day): $40

12,000 BTU Inverter:

- Runs continuously at 40% power

- Zero cycling

- Power consumption: 450 watts average

- Monthly cost (10 hr/day): $16

- Savings: $24/month (60%)

Annual Savings:

- 6-month cooling season: $144/year

- 15-year lifespan: $2,160 savings

- ROI: Inverter premium pays for itself in 2-3 years

Comfort Benefits

Temperature Precision:

Non-Inverter:

- Temperature swings: ±3-4°F

- Set to 72°F

- Actual range: 68-76°F

- You feel the swings

Inverter:

- Temperature swings: ±0.5-1°F

- Set to 72°F

- Actual range: 71-73°F

- Consistent comfort

Humidity Control:

Non-Inverter:

- Dehumidifies only when running

- Humidity swings: 45-65%

- Clammy feeling when off

- Mold risk in humid climates

Inverter:

- Continuous dehumidification

- Steady humidity: 45-55%

- Consistently comfortable

- Better air quality

Noise Reduction:

Non-Inverter:

- Loud startup

- Full-speed operation

- Abrupt stops

- Sleep disruption

Inverter:

- Quiet ramp-up

- Low-speed operation most of time

- No sudden changes

- Whisper-quiet: 19-35 dB

Lifespan & Reliability

Mechanical Stress:

Non-Inverter:

- 6-12 full starts per hour

- 50-100+ starts per day

- 18,000-36,000 starts per year

- High wear on compressor

- Average lifespan: 10-12 years

Inverter:

- 1-2 starts per day typically

- Runs continuously at low power

- 365-730 starts per year

- Minimal wear on compressor

- Average lifespan: 15-20 years

Component Longevity:

Parts that last longer with inverter:

- Compressor: 50% longer life

- Fan motors: 40% longer life

- Capacitors: 60% longer life

- Contactors: 80% longer life

Warranty Confidence: Most inverter systems carry longer warranties (10+ years) vs. non-inverter (5-7 years) because manufacturers know they'll last.

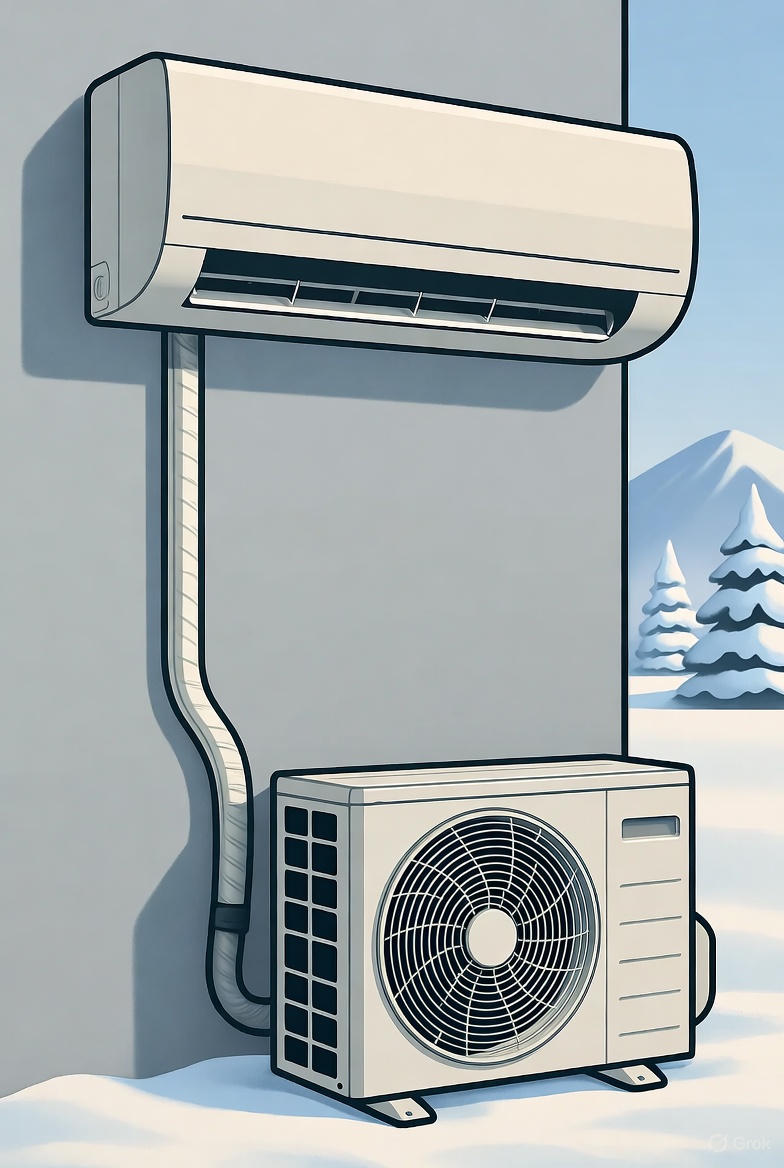

Cold Climate Performance

Why Inverters Excel in Cold:

Heating Efficiency at Low Temps:

At 5°F outdoor temperature:

Non-Inverter Heat Pump:

- Capacity: 50-60% of rated

- Efficiency: 50-70% of rated

- Cycling: Frequent, fighting to keep up

- Backup heat: Runs often (expensive)

Inverter Heat Pump:

- Capacity: 80-100% of rated

- Efficiency: 85-95% of rated

- Operation: Steady high output

- Backup heat: Rarely needed

Variable Capacity Advantage:

In cold weather, inverters can:

- Overdrive to 120% capacity temporarily

- Maintain efficiency at high output

- Optimize for extreme conditions

- Work down to -13°F or lower

Defrost Cycle Optimization:

Non-Inverter:

- Full stop for defrost

- Cold air blast when restarting

- Takes 10-15 minutes to recover

- Disruptive to comfort

Inverter:

- Partial power during defrost

- Minimal temperature drop

- Recovers in 3-5 minutes

- Barely noticeable

Cost Comparison

Purchase Price:

Non-Inverter 12K BTU:

- Equipment: $600-$1,200

- Installation: $1,500-$2,500

- Total: $2,100-$3,700

Inverter 12K BTU:

- Equipment: $1,200-$2,500

- Installation: $1,500-$2,500

- Total: $2,700-$5,000

Price Premium: $600-$1,300

Operating Costs (Annual):

Non-Inverter:

- Electricity: $480/year

- Repairs: $100/year (higher after year 5)

- Total: $580/year

Inverter:

- Electricity: $240/year

- Repairs: $50/year

- Total: $290/year

Annual Savings: $290

Break-Even Analysis:

- Premium cost: $950 (average)

- Annual savings: $290

- Break-even: 3.3 years

- Remaining lifespan: 12-17 years

- Lifetime savings: $3,500-$5,000

Types of Inverter Technology

Standard Inverter:

- Variable speed: 20-100%

- SEER2: 18-20

- Common in mid-range units

DC Inverter:

- More precise control

- Higher efficiency

- SEER2: 20-22

- Better at extremes

Full DC Inverter:

- Outdoor + indoor fans also variable

- Maximum efficiency

- SEER2: 22-24+

- Premium option (Zone uses this)

Dual or Multi-Inverter:

- Two compressors

- Even finer control

- Redundancy

- Commercial applications mainly

Identifying Inverter Systems

Marketing Terms (All Mean Inverter):

- Variable Speed

- DC Inverter

- Inverter Technology

- Variable Capacity

- Modulating

- VRF (Variable Refrigerant Flow)

How to Verify:

- Check SEER2 rating (18+ likely inverter)

- Look for "variable speed" in specs

- Check energy label

- Ask specifically

- Higher price usually indicates inverter

Red Flags for Non-Inverter:

- Very low price

- SEER2 below 16

- "Single speed" listed

- "On/off compressor"

Common Misconceptions

Myth: "Inverters are new/untested" Truth: Inverter AC technology has been mainstream since the 1980s in Asia, 2000s in US. Proven reliability.

Myth: "Inverters are too expensive" Truth: With energy savings and rebates, total cost of ownership is lower than non-inverter.

Myth: "All mini-splits have inverters" Truth: Budget mini-splits may be non-inverter. Always verify.

Myth: "Inverters don't work in cold weather" Truth: Inverters perform BETTER in cold than non-inverter systems.

Myth: "Inverters are harder to repair" Truth: Simpler than you'd think. Most parts standardized. Longer lifespan means fewer repairs needed.

Real-World Performance Data

Zone Customer Data (12K BTU, Texas Summer):

Non-Inverter (Previous System):

- Runtime: 8 hours/day at full power

- Monthly usage: 720 kWh

- Cost at $0.12/kWh: $86.40

Zone Inverter System:

- Runtime: 22 hours/day at variable power

- Monthly usage: 280 kWh

- Cost at $0.12/kWh: $33.60

- Savings: $52.80/month

Northeast Heating (Vermont, January):

Non-Inverter Heat Pump:

- Backup electric heat: 60% of time

- Monthly usage: 1,800 kWh

- Cost at $0.18/kWh: $324

Zone Inverter System:

- Backup heat: 5% of time

- Monthly usage: 950 kWh

- Cost at $0.18/kWh: $171

- Savings: $153/month

Environmental Impact

Carbon Footprint Reduction:

Inverter system over 15-year life:

- Electricity saved: 45,000-65,000 kWh

- CO2 reduced: 25-35 tons

- Equivalent to: 65,000 miles not driven

Refrigerant Efficiency:

Better efficiency means:

- Smaller refrigerant charge needed

- Less refrigerant leaked over time

- Lower global warming potential

Is Inverter Technology Worth It?

Inverter Makes Most Sense:

- Daily use year-round

- Hot or cold climate extremes

- Long-term home ownership

- High electricity rates

- Value comfort and quiet

- Environmental concern

Non-Inverter Might Work:

- Very occasional use only

- Extremely mild climate

- Very tight budget

- Short-term rental property

But Even Then: With Zone's direct pricing, our inverter systems cost less than many competitors' non-inverter models, making the choice obvious.

Zone's Inverter Technology

Zone Systems Feature:

- Full DC inverter technology

- Variable speed: 25-110% capacity

- SEER2: up to 24

- HSPF2: up to 12.5

- -13°F heating operation

- Ultra-quiet: 19 dB minimum

Why Zone Inverters Cost Less:

- Direct-to-consumer sales

- No dealer markup

- Efficient manufacturing

- Volume pricing

- We control the entire supply chain

Comparison:

Same Inverter Technology:

- Mitsubishi/Daikin: $3,500-$5,000

- Zone: $1,800-$2,800

- Performance: Identical SEER2/HSPF2

- Savings: $1,700-$2,200

The Bottom Line

Inverter technology is the single biggest advancement in HVAC efficiency in the past 30 years. The benefits compound:

Energy Savings: 30-50% less electricity Comfort: ±1°F vs ±4°F temperature swings Quiet: 19-35 dB vs 50-65 dB operation Lifespan: 15-20 years vs 10-12 years Reliability: Fewer mechanical failures

Total Value:

- Purchase premium: $600-$1,300

- Lifetime savings: $3,500-$5,000

- Net benefit: $2,200-$3,700

Plus intangibles:

- Better sleep quality

- Quieter home

- Consistent comfort

- Environmental impact

Our Recommendation: Always choose inverter technology. The upfront cost difference pays back quickly, and the long-term benefits are undeniable.

Frequently Asked Questions

What is inverter technology in mini splits and how does it work?

Inverter technology allows mini split compressors to operate at variable speeds from 20-100% capacity instead of just ON or OFF like traditional systems. Think of it like a dimmer switch versus a light switch. The inverter converts electrical power to variable frequencies, precisely controlling the compressor motor speed to match your exact cooling or heating needs. When your room is close to the desired temperature, the inverter reduces compressor speed to 20-40% rather than shutting off completely. This continuous operation at lower speeds uses dramatically less energy than repeatedly starting and stopping at full power. The system constantly monitors temperature and makes micro-adjustments every few seconds, maintaining your set temperature within ±1°F instead of the ±4°F swings you experience with non-inverter systems. Modern inverter mini splits use "full DC inverter" technology where both the compressor and fan motors operate at variable speeds, maximizing efficiency across all operating conditions. Zone DIY Series systems feature this premium full DC inverter technology in all models.

How much more efficient are inverter mini splits compared to traditional systems?

Inverter mini splits use 30-50% less electricity than non-inverter systems for the same cooling or heating output. Real-world data shows dramatic savings: a 12,000 BTU inverter system costs approximately $33.60 monthly to operate in a hot climate versus $86.40 for a non-inverter system—that's $52.80 monthly savings or $634 annually. Over a 15-year lifespan, you'll save $9,500 in electricity costs while enjoying superior comfort. The efficiency advantage comes from three sources. First, inverters eliminate wasteful start-up energy surges—traditional systems draw 40-60 amps during startup versus just 12-18 amps for inverters. Second, continuous low-speed operation proves far more efficient than repeated full-power cycling. When your space needs only 40% capacity on a mild day, an inverter runs continuously at 450 watts while a non-inverter cycles between 1,100 watts and zero, averaging higher consumption. Third, inverters excel at part-load conditions, maintaining 90-95% efficiency when running at reduced speeds versus 60-70% for non-inverter systems constantly cycling. The efficiency gap widens further in moderate weather when your space needs minimal conditioning—exactly when you're using the system most. Cold climate performance shows even more dramatic efficiency gains, with inverters maintaining 85-95% rated efficiency at 5°F outdoor temperature while non-inverter heat pumps drop to 50-70% efficiency and require expensive backup electric heat.

Are inverter mini splits worth the extra cost?

Absolutely—inverter mini splits typically pay for themselves within 2-4 years through energy savings alone, then continue delivering value for another 12-18 years. The purchase premium runs $600-$1,300 for inverter technology, but annual operating cost savings average $240-$290 compared to non-inverter systems. Break-even occurs around year 3, after which you're pocketing pure savings totaling $3,500-$5,000 over the system's 15-20 year lifespan. But the value equation extends beyond just energy costs. Inverter systems last 50% longer than non-inverter units (15-20 years versus 10-12 years) because continuous low-speed operation creates far less mechanical wear than constant full-power cycling. A non-inverter compressor starts 50-100 times daily, accumulating 18,000-36,000 high-stress starts annually. Inverters start just 1-2 times daily—365-730 starts yearly—dramatically extending compressor life. Repair costs run lower too, averaging $50 annually for inverters versus $100+ for non-inverter systems. Federal tax credits and utility rebates often offset $700-$1,500 of the inverter premium, reducing your actual out-of-pocket difference to near zero. Finally, consider comfort value: eliminating ±4°F temperature swings, achieving quiet 19-35 dB operation instead of disruptive cycling noise, maintaining consistent humidity control, and enjoying better cold-weather performance all deliver daily quality-of-life improvements worth far more than the small upfront premium.

Do all mini splits have inverter technology?

No—budget mini splits and older models often use traditional fixed-speed compressors without inverter technology. Always verify before purchasing, as the difference dramatically affects performance and operating costs. Most mini splits with SEER2 ratings of 18 or higher feature inverter technology, while ratings below 16 SEER2 often indicate non-inverter systems. Marketing terms that confirm inverter technology include "variable speed compressor," "DC inverter," "inverter technology," "variable capacity," "modulating compressor," or "VRF" (Variable Refrigerant Flow). Manufacturers sometimes obscure this distinction, so ask explicitly: "Does this model have inverter technology or a variable-speed compressor?" Red flags indicating non-inverter systems include suspiciously low prices ($800-$1,200 for a 12K BTU unit), specifications listing "single speed" or "on/off compressor," SEER2 ratings below 16, and absence of efficiency-related marketing language. Budget brands selling through big-box retailers often offer non-inverter models to hit aggressive price points, sacrificing efficiency and comfort for lower sticker prices. All Zone DIY Series systems feature full DC inverter technology with variable-speed compressors—we don't offer non-inverter models because the long-term value doesn't justify the small upfront savings. When comparing quotes from contractors, verify whether their pricing includes inverter or non-inverter equipment. A $3,500 installed price for an 18 SEER2 inverter system represents better value than $2,800 for a 14 SEER2 non-inverter system once you factor in 15 years of operating costs.

How long do inverter mini splits last compared to traditional systems?

Inverter mini splits typically last 15-20 years with proper maintenance, compared to 10-12 years for non-inverter systems—roughly 50-60% longer lifespan. This longevity difference stems from dramatically reduced mechanical stress. Non-inverter compressors experience 50-100 full-power starts daily, each creating maximum mechanical and thermal stress on bearings, pistons, and motor windings. Over a 10-year lifespan, that's 180,000-365,000 high-stress start cycles. Inverters start just once or twice daily at reduced power, accumulating only 3,650-7,300 gentle starts over 10 years—98% fewer stress cycles than non-inverter systems. Continuous low-speed operation maintains steady operating temperatures without thermal cycling, prevents oil slugging that damages compressors, reduces vibration stress on mounting points and refrigerant connections, and eliminates wear from repeated electrical inrush current. Every component benefits from this gentler operation: compressor life increases 50%, fan motors last 40% longer, capacitors survive 60% longer, and contactors endure 80% longer. Manufacturers demonstrate their confidence in inverter longevity through warranties—most inverter systems carry 10-year compressor warranties versus 5-7 years for non-inverter units. Real-world data supports these expectations: well-maintained inverter mini splits regularly exceed 18 years of reliable service, while non-inverter units typically fail between years 8-12. The extended lifespan effectively reduces your per-year ownership cost from $300-350 for non-inverter systems to $140-160 for inverter units, making the higher-efficiency option cheaper annually despite the upfront premium. When a mini split fails early, it's almost always non-inverter technology succumbing to accumulated start-cycle stress.

Are inverter mini splits quieter than traditional systems?

Dramatically quieter—inverter mini splits operate at 19-35 decibels most of the time versus 50-65 decibels for non-inverter systems cycling at full power. That 30-decibel difference represents sound intensity reduction of roughly 90%, transforming your mini split from a disruptive appliance into barely-noticeable background whisper. The quietness advantage comes from continuous low-speed operation rather than full-blast cycling. When your inverter system maintains temperature, it runs at 20-40% capacity producing just 19-25 dB—quieter than a library, comparable to rustling leaves or quiet breathing. Non-inverter systems only know one speed: maximum, generating 50-58 dB continuous noise whenever running, equivalent to normal conversation volume or a busy office. Even worse, non-inverter systems create jarring start-stop cycles every 10-20 minutes—sudden loud startup followed by abrupt silence, then repeating indefinitely. These cycles destroy sleep quality and interrupt conversations or TV watching. Inverters ramp up and down gradually without sudden changes, maintaining steady quiet operation that your brain quickly filters out as unimportant background sound. Bedroom installations showcase this difference most dramatically. One couple replaced their 55 dB window unit with a Zone inverter mini split and reported their first full night's uninterrupted sleep in six years—they'd become conditioned to their old unit's noise cycling but didn't realize how severely it fragmented their sleep until experiencing truly quiet operation. During phone calls or video meetings, non-inverter AC units force you to either sweat through calls with the system off or apologize for background noise. Inverter systems run continuously at 22-28 dB—quieter than your laptop fan, completely inaudible during calls. The outdoor units show similar advantages, operating at 48-52 dB at low speeds versus 58-65 dB at full power for non-inverter systems, reducing neighbor complaints and improving outdoor space enjoyment.

Do inverter mini splits work better in cold weather than traditional systems?

Yes—inverter mini splits dramatically outperform traditional systems in cold weather, maintaining 80-100% rated heating capacity at 5°F outdoor temperature compared to just 50-60% for non-inverter heat pumps. This performance gap widens as temperatures drop further: at -5°F, inverters still deliver 70-85% rated capacity while non-inverter systems struggle at 30-40% capacity, forcing reliance on expensive backup electric resistance heat. The advantage comes from variable-speed technology that optimizes for extreme conditions. When outdoor temperatures plummet, inverters can temporarily overdrive to 110-120% capacity to quickly heat your space, then settle back to efficient steady-state operation. Non-inverter systems stuck at single-speed operation simply can't generate enough heat when outdoor conditions turn hostile. Real-world Vermont data illustrates this perfectly: during January with average lows around 5°F, a non-inverter heat pump required backup electric heat 60% of the time, consuming 1,800 kWh monthly at $324 cost. A Zone inverter system in identical conditions needed backup heat only 5% of the time, consuming 950 kWh monthly at $171 cost—53% savings. Inverter systems also handle defrost cycles far better in cold weather. When frost accumulates on outdoor coils, non-inverter systems must stop completely for 10-15 minutes while defrosting, blasting cold air into your home and requiring long recovery times. Inverters continue running at partial power during defrost, maintaining indoor comfort with minimal temperature drop and recovering in just 3-5 minutes. Cold-climate certified inverters from Zone operate reliably down to -13°F outdoor temperature, providing 100% of rated heating capacity at 5°F—the temperature where most heating occurs during northern winters. Below -13°F, the system smoothly transitions to backup heat without the cycling struggle typical of non-inverter systems. This reliable cold-weather performance makes inverter technology essential for anyone relying on heat pumps for winter heating in climates experiencing regular temperatures below 25°F.

Ready to experience the efficiency of modern inverter technology? Check out Zone's premium inverter systems with SEER2 ratings up to 24.

Questions about how inverter systems work? Our technical team is available 24/7 at (801) 882-2324.